Product information "ENGAGE4X4 Heavy Duty Antriebswellen Kit Vorder- & -Hinterachse"

Neu! ENGAGE4X4 Fahrzeug-Antriebswellen-Satz verstärkt

Der ENGAGE4X4 Antriebswelle-Satz mit verstärkten Steckachsen und Gleichlaufgelenken ist die ideale Lösung für hochbelastete Land Rover Defender, die in anspruchsvollem Offroad-Gelände oder auf Langstreckenexpeditionen im Einsatz sind. Hergestellt in Deutschland und speziell für extreme Belastungen konzipiert, bietet dieser Antriebswelle-Satz höchste Stabilität und Haltbarkeit – selbst unter härtesten Bedingungen. Die integrierten Gleichlaufgelenke (Homokineten) sorgen für eine gleichmäßige Kraftübertragung, selbst bei maximalen Achsverschränkungen und starker Beanspruchung auf unebenem Terrain.

ENGAGE4X4 Heavy Duty Antriebswelle-Fahrzeug-Satz

Der ENGAGE4X4 Satz wird nach höchsten OEM Daimler Qualitätsstandards gefertigt und erfüllt die strengen TS16949 und ISO 9001 Anforderungen. Dies gewährleistet nicht nur eine exakte Passform und höchste Präzision, sondern auch die Sicherheit und Zuverlässigkeit, die für Offroad-Abenteuer und Fernreisen unverzichtbar sind. Mit den verstärkten Steckachsen und robusten Homokineten bietet dieser Antriebswelle-Satz eine exzellente Lebensdauer und ist speziell für den Einsatz an Land Rover Defender Modellen ausgelegt. Die hochbelastbaren Steckachsen verhindern Brüche und Schäden in schwierigem Gelände und garantieren eine reibungslose Leistungsübertragung in jeder Situation.

ENGAGE4X4 Antriebsstrangteile für Defender

Der ENGAGE4X4 Antriebswelle-Satz ist damit die erste Wahl für Offroad-Enthusiasten und Profis, die auf ihrem Defender kompromisslose Qualität und Zuverlässigkeit für echte Abenteuer suchen.

Erleben Sie maximale Performance und Robustheit mit ENGAGE4X4 – die Lösung für alle, die ihren Land Rover Defender auf das nächste Level bringen möchten.

Zubehör Artikel

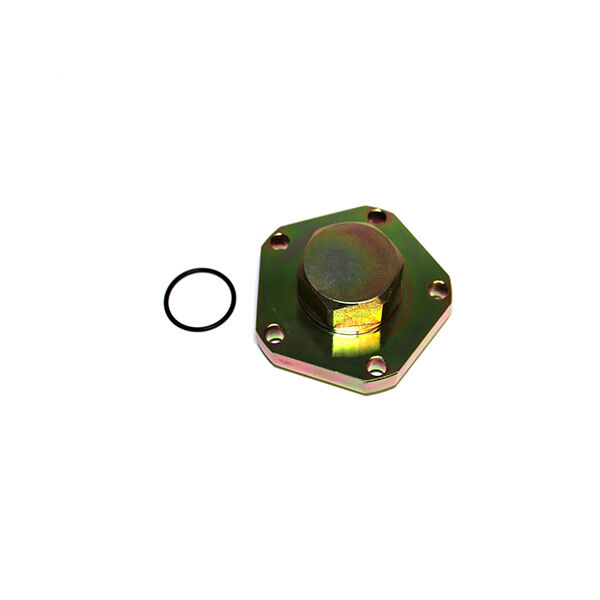

Reinforced wheel hitch Land Rover Defender Heavy duty wheel hubs for Land Rover Defender with screw cap. For vehicles that are used under adverse conditions in the terrain, work or trailer operation. The screw cap reliably prevents the ingress of dirty water when driving through water and protects the wheel bearings from damage. Durability for off-road and long-distance travel A reliable drivetrain is especially important for long-distance travel and expeditions and off-road use. Reinforced CNC milled wheel drivers also protect the gearing of the drive shafts and thus extend durability. Heavy Duty wheel drivers made from 41CRoMoV5 are more accurately manufactured and wear out more slowly. The better fit reduces load-shedding in the driveline. Information Fits all Defender from 1994 > 2016 Material 41CroMoV5 Surface black powder coated or yellow galvanized

Reinforced wheel hitch Land Rover Defender Heavy duty wheel hubs for Land Rover Defender with screw cap. For vehicles that are used under adverse conditions in the terrain, work or trailer operation. The screw cap reliably prevents the ingress of dirty water when driving through water and protects the wheel bearings from damage. Durability for off-road and long-distance travel A reliable drivetrain is especially important for long-distance travel and expeditions and off-road use. Reinforced CNC milled wheel drivers also protect the gearing of the drive shafts and thus extend durability. Heavy Duty wheel drivers made from 41CRoMoV5 are more accurately manufactured and wear out more slowly. The better fit reduces load-shedding in the driveline. Information Fits all Defender from 1994 > 2016 Material 41CroMoV5 Surface black powder coated or yellow galvanized

Reinforced wheel hubs - Land Rover Defender In heavy off road use or trailer operation, all drivetrain components are subject to increased wear. Especially the original cast wheel drivers, have problems with the gearing under extreme loads. Another problem favors the rapid wear, over rubber caps gets in the dirty water in the gearing, by the finest sand, and dirt particles, the gearing works itself out over time piece by piece. The load change beating of your Land Rover Defender is increasingly stronger. In extreme cases, the stub axle in the wheel driver can even spin. Wheel hubs with screw caps, on the other hand, do not have this problem. They are much more durable and the material is much stronger than the original wheel drivers. Field of application: Off Road Trailer use Work vehicles Material: 5140 steelSurface: Yellow galvanizedScope of delivery: Screw cap & driver Information Installed quantity / vehicle 4 pieces (quantity to be ordered 2 sets) Reinforced version Suitable for Land Rover Defender from VIN LA > end of production, Discovery 1 & Range Rover Classic from VIN JA to end of production Installation advice: Recommended is not to use the original paper gasket and to use silicone RTV Black.Installed from: VIN - KA430456 narrow - designOE part number: RUC105200 FRC

Wheel hitch bolt set non-rusting for all Defender Geomet coated. The screws of the wheel drivers of the Land Rover Defender rust after every winter and it just doesn't look nice anymore. Stainless steel bolts unfortunately cannot be used at this point for various reasons. We have now had a special set of screws manufactured with a high quality Geomet coating with a 465 hour salt spray test. In comparison normal galvanized screws have 120 hours. The original Land Rover screws burnished about 50 hours. The strength class (quality) corresponds to the prescribed original Land Rover screws of 10.9, the yield strength is over 900 Nm. The bolts are manufactured in the EU. Wheel driver bolts Defender Geomet Included in delivery are 20 special screws for all 4 wheel drivers and 1x 3 ml threadlocker "medium strength". Information Screw M10x45 Surface Geomet 500A Grade 10.9 Yield strength 900 Nm

Die One Shot Fließfett-Füllung für das Gleichlaufgelenk Das Fließfett ist speziell formuliert und ausgelegt für alle Land Rover Serie 1-III, Defender, Discovery- und Range Rover Classic-Modelle mit Blatt- und Schraubenfeder - 1951 - bis heute. Es schmiert Gleichlaufgelenke (Homokineten), schützt die Gehäusedichtungen und Gleichlaufgelenk-Gehäuse. Informationen Ein halbflüssiges Fett, dass Stoßbelastungen in schwingenden Verbindungen standhält. Mit Festschmierstoffen verstärkt, sehr widerstandsfähig gegen Wasser und Salzkorrosion. Bessere Schmierung während der Fahrt, weniger Lecks im Stehen. Bitte beachten Sie:Wir haben zwei Hersteller des Fließfetts und die Verpackung kann unterschiedlich sein. Das Fließfett ist inhaltlich identisch und es gibt keine Qualitätsunterschiede.

Content: 370 Gramm (€0.04 / 1 Gramm)

Flüssig-Fett für Schwenklager-Gehäuse Fett für das Gleichlaufgelenk im Schwenklagergehäuser bei allen Defender, Discovery 1 und Range Rover Classic Modellen. Informationen Benötigte Menge / Fahrzeug 2 Stück (bei leeren Gehäusen) Qualität Nachbau Verpackung Flasche

Content: 500 Gramm (€0.04 / 1 Gramm)

Wheel Bearing Nut Defender TD5 and TD4 Wheel bearing nut Land Rover Defender from year of manufacture 1999 until end of production 2016 in OEM parts quality. Fits all Defender TD5 and TD4 models. Wheel bearing nut Defender from year of manufacture 1999 until 2016 is an OEM spare part for Land Rover Defender. This wheel bearing nut is specifically designed to fit the stub axle of the Defender and has a special locking surface to ensure a secure fitment. This replacement part is suitable for all Defender models from 1999 to 2016. Information Installed quantity / vehicle 4 pieces Quality OEM Suitable for Defender from 99 > 2016

Land Rover Defender Wheel Bearing Repair Kit Wheel bearing repair kit for all Land Rover Defender front and rear axle from chassis number (VIN) LA > Information Installed quantity 4 Fits Defender (all) from VIN LA > For front axle & rear axle Parts quality (replica) not recommended for off-road use or adverse conditions

Land Rover Defender Wheel Bearing Repair Kit Wheel bearing repair kit in OEM parts quality comes with all small parts and special bearing wheel bearing grease. Suitable for all Defender front axle & rear axle. Information from chassis number LA930456 until end of production Suitable for Defender TDI 300 from VIN LA930456, TD5, TD4 OEM quality installed quantity per vehicle 4 sets

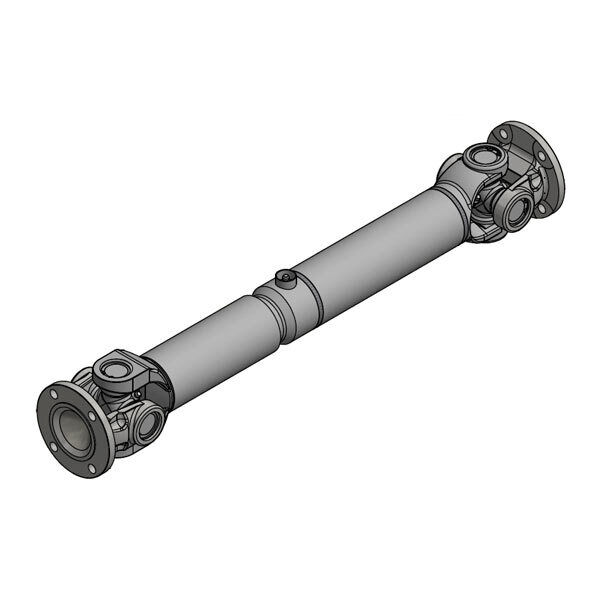

ENGAGE4X4 Wide Angle Cardan Shaft Defender Cardan shafts from ENGAGE4X4 are made in Germany and are only manufactured with OE parts to ensure long durability. All cardan shafts have been tested, developed and continuously improved by us over many years. The universal joints are much stronger than the original standard joints. ENGAGE4 Wide Angle Cardan Shaft Defender for high durability in off-road conditions The ENGAGE4X4 cardan shafts are designed for very heavy loads in off-road operation. The sliding piece of this Defender propshaft is protected from the ingress of dirty water by a Simmering. The reinforced universal joints are equipped with special PU thrust washers (high performance seal) according to construction machinery standard. The universal joints can be lubricated centrally. The shaft operates stress-free at a large entanglement at an angle of up to 30°. ENGAGE4X4 wide angle cardan shafts are of great advantage on Defenders with a low chassis lift max. 20 mm and a higher axle articulation. Thus, the universal joints are not overstressed in the deflected state. The sliding piece with over 110 mm length compensation can be lubricated on all shafts since 2014. The grease nipple is protected from tearing off by a metal ring. So that the shaft can still be maintained even after extreme off-road use. Information Areas of application, off road, trophy, rally raid, protected vehicles, higher vehicles Cross sets reinforced 30 mm with PU thrust washers (greasable) Length compensation 110mm Sliding piece toothing plastic coated and sealed with Simmering (greasable) Fits original Defender flange Manufacturer Standard: ISO:9001 & TS:16949

The Defender Limited Slip Differential - ATB Automatic Torque Biasing - Limited slip differential. The Land Rover Defender Limited Slip Differential ATB is a so-called "Helical Gear" differential - with six gear pockets. It increases the off-road capability of the Defender many times over. There are a number of other Limited Slip differentials available for the Land Rover Defender, Discovery 1 or Range Rover Classic. Such as the Limited Slip with a friction disc clutch and the TYPE T1 Torsen.The Torsen T1 was the predecessor of today's ATB differentials. Friction disc LSD differential - obsolete technically with high wear and tear An ATB differential is technically and from the durability clearly superior to the friction disc variant. Especially at very high loads under adverse conditions and the associated wear, which acts perpetually on the organic friction discs. With the friction disc differential, high friction is required to reduce slip on the drive wheels. This high preload results in harsh vibration effects and causes high premature wear. The Torsen T1 differential was based on a mechanical principle. To produce transverse torque, effectively coupled worm and gear wheels are driven backwards to produce the required frictional loads. These often failed under this high load, and the worm gears were destroyed after not too long of use. The ATB differential (Automatic Torque Baisin) is the helical type and has many advantages. ATB differentials are practically imperceptible to the driver during normal road driving, since the friction between the gear and guide does not intervene. Disadvantage and explanation of handling in off-road use One disadvantage of the ATB Limited Slip Differential is that one wheel per axle must always be loaded to be effective. If there is no load situation, for example a drive axle, the wheel with traction would be loaded about three times as much as the wheel without traction. This means that there is no 100% propulsion here. To overcome this problem, the Defender Limited Slip Differential, is equipped with some preload springs, and the trick is to lightly apply the brake with your left foot while giving it some throttle. This maneuver fools the differential by distributing a load to the slip side. On the Land Rover Defender ATB differential, the load distribution is about 3: 1, which is multiplied to the other side. The loss of drive, therefore, attributed to the trick with the brake, thus distributes the power evenly to both wheels. In a vehicle with automatic traction control, this braking is automatically simulated by the ABS Modulator. The ATB differential provides additional traction by multiplication on Defender models with Traction Control (TC). Mounting and accessories for Land Rover Defender and Discovery 1 models The Land Rover ATB differential can be mounted at the front or rear. On the front axle, the Defender's tracking through the steering will be slightly higher compared to the standard differential. You will notice this stiffer steering very little when cornering. So why use an ATB instead of a 100% differential lock? When riding on a low traction surface, such as, sand, snow or wet grass, you could cause some loss of traction when cornering with a 100% differential lock. This is because both wheels are driven at the same speed. The ATB lock allows the difference in wheel speed to be equalized even on loose surfaces, but at the same time tries to equalize the torque at each wheel. This reduces the possibility of a so-called spin-out situation. When mounting for Defender 110 and 130 rear axle, an adapter kit is still needed. For Defender 90, Discovery 1 and Range Rover Classic the differentials for front & rear axle are the same. Safety Note: Due to the nature of the ATB differential, we do not recommend vehicle with lock on a roller brake tester. Mounting Note: When mounting for Defender 110 and 130 rear axle, an adapter kit is still needed. For Defender 90, Discovery 1 and Range Rover Classic the differentials for front & rear axle are the same.

Double-joint propshaft Land Rover Defender When the chassis is raised more than 25 mm, rotational vibrations occur in the driveline of the Defender TD4. These mostly occur in the, at a speed of slightly more than 80 km/h and can damage the transfer case in the long run. The ENGAGE4X4 double-joint propshaft prevents the vibrations in the driveline of the raised Defender through a stress-free working angle. In this way, height increases of around 100 mm are possible. Thus, the ENGAGE4X4 double-joint propshaft is absolutely necessary for Land Rover Defenders with a suspension lift, in order to carry out a durable suspension modification on the Defender. Another special feature is the new lubricatable sliding piece developed by ENGAGE4X4, here the grease nipple is protected, so that the shaft can be maintained even after extreme off-road use. Continuous improvement and long-term testing in our vehicles. In 2018, a journey was started from Germany to Mongolia and back around 20,000 km, including 3,500 km under the most adverse conditions in the steppe of Mongolia and many off-road passages in Russia and Kazakhstan. The ENGAGE4X4 double-jointed cardan shaft had been installed for more than 6 years at this point and had run 45,000 km with a suspension increase of 80 mm. Also on this tour no defect was found at the shaft. Our ENGAGE4X4 double-joint cardan shaft has gone through a steady improvement trip over 9 years. Countless improvements, tests with the manufacturer and durability tests as well as long-term tests over years have made this propshaft unique. Available for all Land Rover modelsFor the Land Rover Defender suitable for the front axle and the Defender 90 TDI & TD5 suitable for the rear axle. The ENGAGE4X4 propshafts are designed for very heavy duty off road use. The sliding piece of this Defender propshaft is protected with a Simmering against the penetration of dirty water. The reinforced universal joints can be lubricated. The shaft operates stress-free at large interlocks at angles up to 35°. Information Land Rover Defender TD4 (all models) on the front axle Land Rover Defender 90 TD5 & TDI on rear axle Cross sets: Reinforced 30mm (greasable) Length compensation: 110mm Sliding piece: Toothing plastic coated and sealed with Simmering (greasable) Flange: Fits flange (original Defender flange) Manufacturer Standard: ISO:9001 & TS:16949 ApplicationsOff Road, Trophy, Rally Raid, protected vehicles, higher mounted vehicles, expedition vehicles for long distance travel

Pneumatic 100% Differential Lock for Defender 110 & Discovery 2. There are many types of 100% differential locks for Landrover vehicles, but all seem to have a weak point in the design. The ASC differential lock has been tested by us over many years in extreme conditions. Offroad differential lock for Land Rover vehicles This is a perfectly designed 100% pneumatic differential lock. It can be mounted in the original Land Rover differential housing with minimal installation effort, i.e. without modifications to the axle housing. An electric differential lock and is significantly less reliable than a good accurately machined pneumatic version. One of the main requirements of the ASC lock, is absolutely no pressure loss, as this is one of the main problems with other air operated pneumatic locks. To achieve this, a static piston has been used instead of a rotating seal, which has been used in other valves and tends to leak in 80% of all assembled valves. The ASC lock was also made sure to have a full 6 mm engagement when locked, as other air locks are only 2.5 mm and can slip out of lock engagement when loaded. The final design was eventually based on a 4 pin differential center, this is a heavy duty variant of the original Land Rover differential. This has a 2 pin differential center in comparison and is therefore much weaker balanced. One of the differential side gears has an outer ring of claw teeth to engage the lantern ring when locked, so the lantern ring is crown wheel side. The lantern ring is held in place with 4 pins that pass through the diff center Non crown gear side. Outside the diff center, the 4 pins are connected to a steel thrust ring. This assembly forms a sturdy steel cage, not plastic like other designs that tend to fail. Technical description and function On the non-rim end of the journal end cap is a cylinder that houses a bronze piston. The piston has a groove around the inside and outside diameters into which O-rings are inserted. Once the piston is assembled, a retaining ring is threaded around the stud End of cylinder To keep the piston from exiting, air is supplied to the cylinder through a copper tube to a 90-degree ferrule that fits the outside diameter of the cylinder. When air is applied, the piston moves along the cylinder until it reaches the retaining ring. The cylinder does not rotate, the cylinder is stationary and sits on a bronze bushing on the side of the diff center. Inside the sleeve bearing on the cylinder side is a bronze thrust ring to hold the cylinder in place. A locking tab is attached to one of the bolts on the bearing journal cap and is located in a recess in the cylinder to stop rotation. Information Defender 110 - 1993 to rear axle Discovery 2 - 1998 - 2004 Front & Rear Axle Range Rover P38 - 1996-2002 Front & Rear Axle

ENGAGE4X4 100% Air Differential Lock Defender Differential lock for Defender is indispensable for long-distance travel and off-road vehicles. The reinforced design provides better durability and more safety during travel. The construction and special design of the lock as well as quality of the materials make the ENGAGE differential lock a quality product. A top price-performance ratio ENGAGE4X4 air differential locks, based on a compressed air control, immediately provide 100% traction for your Land Rover Defender in off-road use. In almost any terrain, whether it is sand, stone, mud or gravel. Equipped with two differential locks your vehicle is at home everywhere whether on slopes, in the high mountains, forests or in desert areas. Modern technology - durable differentials in Defender The 100% locks are known with your design, with high-strength planetary gears for extremely high strength and durability. Are ENGAGE4X4 reinforced differential locks better than the original differentials? Many Defender drivers believe that four wheel drive and traction go hand in hand. Unfortunately, a simple all-wheel drive is not enough for real terrain. With a 100% differential lock, the Defender is much more capable off-road. Original and alternative Defender differentials The original differential of the Land Rover Defender allows each wheel to turn independently. Off-road, this is a disadvantage. With a locked differential, both wheels must turn the same during cornering. Here, a locked differential means 100% on each wheel. Newer models have traction control. You will find that off-road traction is not sufficient to propel the Defender. Automatic limited slip differentials also have their disadvantages. Aside from the fact that they are noisy when disengaged, and they affect the handling characteristics of your vehicle on the road.

Defender 100% pneumatic differential lock for P38 rear axle. A 100% pneumatic differential lock for the Land Rover Defender is indispensable for off-road and long-distance travel. The tireless durability of the reinforced differential ensures greater safety. The development and special design of the lock and quality of the materials make the ENGAGE4X4 lock a top product. ENGAGE4X4 air differential locks, based on a well-known technology, provides off-road use for 100% traction of your Land Rover Defender in almost any terrain, whether it is sand, stone, mud or gravel. Modern technology durable differentials in the Defender ENGAGE4X4 100% locks are known for their two-piece design, with high-strength planetary gears for extremely high strength and durability. ENGAGE4X4 Defender differential locks are built better than the original differentials. Many Defender drivers believe that four wheel drive and traction go hand in hand. With a 100% differential lock, the Defender is much more capable off-road. Original and alternative Defender differentials The original differential on the Land Rover Defender allows each wheel to turn independently. Off-road, this is a disadvantage. With a locked differential, both wheels must turn the same during cornering. Here, a locked differential means 100% on each wheel. Newer models have traction control, you will find that off-road traction is not sufficient to propel the Defender. Automatic limited slip differentials also have their disadvantages. Aside from being noisy when disengaged, they both affect the handling characteristics of your vehicle on the road.

Pneumatic 100% differential lock for Defender and Discovery 1. There are many types of 100% differential locks for Landrover vehicles, but all seem to have a weak point in the design. The ASC differential lock has been tested by us over many years in extreme conditions. Offroad differential lock for Land Rover vehicles This is a perfectly designed 100% pneumatic differential lock. It can be mounted in the original Land Rover differential housing with minimal installation effort, i.e. without modifications to the axle housing. An electric differential lock and is significantly less reliable than a good accurately machined pneumatic version. One of the main requirements of the ASC lock, is absolutely no pressure loss, as this is one of the main problems with other air operated pneumatic locks. To achieve this, a static piston has been used instead of a rotating seal, which has been used in other valves and tends to leak in 80% of all assembled valves. The ASC lock was also made sure to have a full 6 mm engagement when locked, as other air locks are only 2.5 mm and can slip out of lock engagement when loaded. The final design was eventually based on a 4 pin differential center, this is a heavy duty variant of the original Land Rover differential. This has a 2 pin differential center in comparison and is therefore much weaker balanced. One of the differential side gears has an outer ring of claw teeth to engage the lantern ring when locked, so the lantern ring is crown wheel side. The lantern ring is held in place with 4 pins that pass through the diff center Non crown gear side. Outside the diff center, the 4 pins are connected to a steel thrust ring. This assembly forms a sturdy steel cage, not plastic like other designs that tend to fail. Technical description and function On the non-rim end of the journal end cap is a cylinder that houses a bronze piston. The piston has a groove around the inside and outside diameters into which O-rings are inserted. Once the piston is assembled, a retaining ring is threaded around the stud End of cylinder To keep the piston from exiting, air is supplied to the cylinder through a copper tube to a 90-degree ferrule that fits the outside diameter of the cylinder. When air is applied, the piston moves along the cylinder until it reaches the retaining ring. The cylinder does not rotate, the cylinder is stationary and sits on a bronze bushing on the side of the diff center. Inside the sleeve bearing on the cylinder side is a bronze thrust ring to hold the cylinder in place. A locking tab is attached to one of the bolts on the bearing journal cap and is located in a recess in the cylinder to stop rotation. Information Defender 90 - 1993 to front & rear axle Defender 110 - 1993 to front axle Discovery 1 - 1993 - 1998 Front & Rear Axle Range Rover Classic - 1993 - 1996 Front & Rear Axle